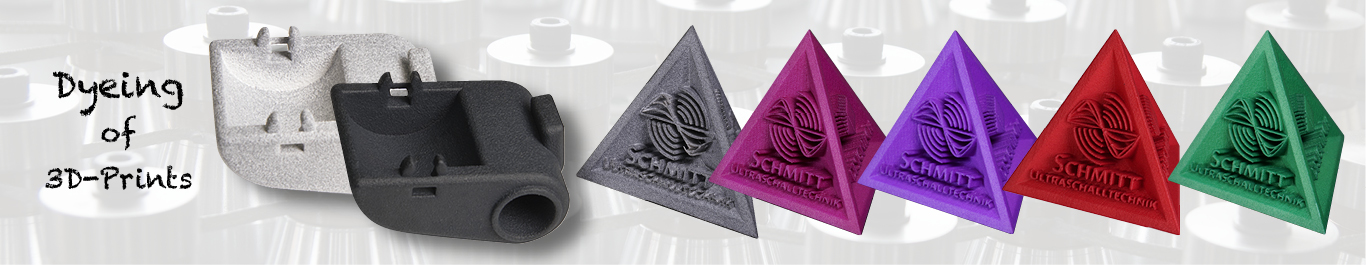

Dyeing 3D prints is a new area we are currently working on.The ultrasound supports the adhesion of the ink pigments on the surface. The continuous compression and decompression results in intense pressure variation (up to 1000 bar), which leads to strong currents in the micro level and therefore to a brush-effect, which removes air bubbles and dust particles from the surface of the parts structure. According tests with MJF, PA, ABS and SLA parts were very satisfying.

To dye 3D-parts we offer three system types:

Solo-Systems with just one basin for dyeing

Duo-Systems with two basins (dyeing and rinsing)

Trio-Systems with three basins (dyeing, rinsing and drying)

(alternatively with two basins for different dyes and one rinsing basin in the centre)

We achieved excellent dyeing results using the GTC dyeing liquids, manufactured by a french company TCN, which are ideally suited for dyeing 3D parts. Suitabele materials are Polyamide, Polyurethane, Acrylic, Resin, Carbon Fiber, Polyester, ABS. https://www.techniques-chimiques-nouvelles.com/en/additive-manufacturing/

- Dyeing time approx 1 to 10 minutes (depending on material)

- Mixing ratio: 1 part dyeing solution with 5 to 10 parts water (depending on material)

- Cost of dyeing liquids: approx. € 25,- (GTC) – € 37,- (GTD) per Liter

- Temperature 60 – 85° C (EOS-, HP- and ABS prints)

- Temperature 25°C – 40°C (Polyjet & SLA-prints)

- Basket Volume from 20 Liter

- Multiple usage of dyeing liquid

- System cost from approx. € 5.280,- (20-Liter-System)

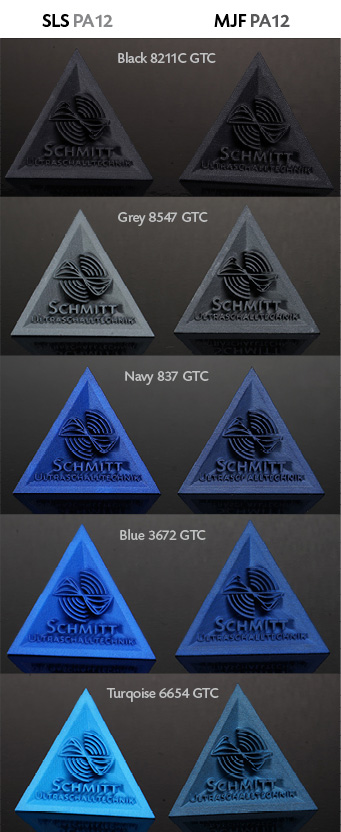

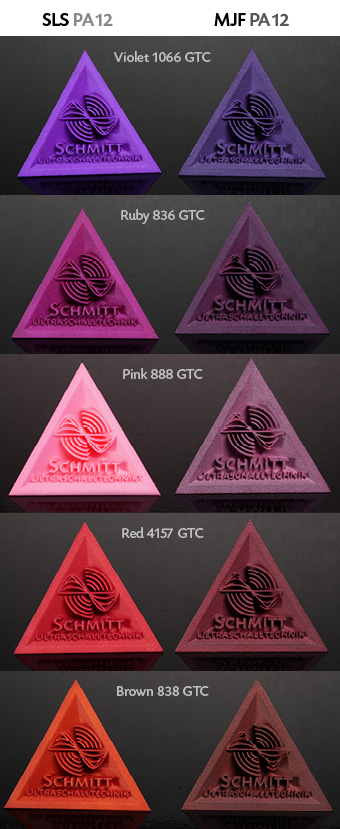

Following you see some samples of our dyed PA12 pyramids. The left photos show SLS pyramids while the right photos show MJF pyramids: