3D-Print Support Removal

SUT offers different systems for current printing methods and materials. As shown right, all systems are available with different volumes as

Solo-Systems with just one basin (cleaning only)

Duo-Systems with two basins (cleaning & rinsing)

Trio-Systems with three basins (cleaning, rinsing and drying)

All system versions can be customised to your individual needs – whether its chambers, volume, ultrasonic power, flushing methods and / or heating.

Variable clampable zoning grids allow to hold down parts in the liquid as well as a vertical zoning of the basket for a targeted positioning of parts in front of (or apart from) the flushing openings (e.g. to protect fragile parts).

FDM-Systems (e.g. Stratasys, Arburg)

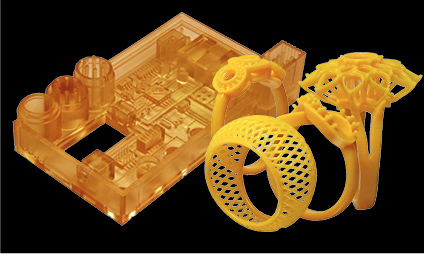

Polyjet- (e.g. Stratasys/Objet) and Mimaki-Systems

SLA-Systems (e.g. envisionTEC, 3D Systems)

- Fast solvent/Isopropanol-free cleaning of SLA print resin residues

- No explosion protection required

- Available as SOLO-, Duo- and Trio-Versions with opt. Caddy

- Systems from 20 to 1000 Liter Volume

- Adjustable Max-Temperature-Control

- Cleaning time approx. 30 minutes

- Interval-Technology: Ultrasound + Turbulent Flow

- Pump preserving, non crystallising cleaner

XXL High Volume Systems (e.g. for Fortus 900 parts)

SUT also manufactures systems to clean and remove support material from large format 3D prints. Theses systems are avilable with and without heating as well as as manual systems (manual loading/unloading) or with an optional hydraulic basket lifting system.

- Multiple installations at car manufacturers and 3D print service providers

- Systems with up to 1000 Liter volume

- Adjustable temperature 30 – 85°C

- Interval-Technology: Ultrasound + Turbulent Flow